-

Advantage Thermally Modified Pine, 1x6 Standard

Save Liquid error (snippets/price line 86): Computation results in '-Infinity'% Call to Order: 1-877-232-3915Regular price $2.40 USDRegular priceUnit price per -

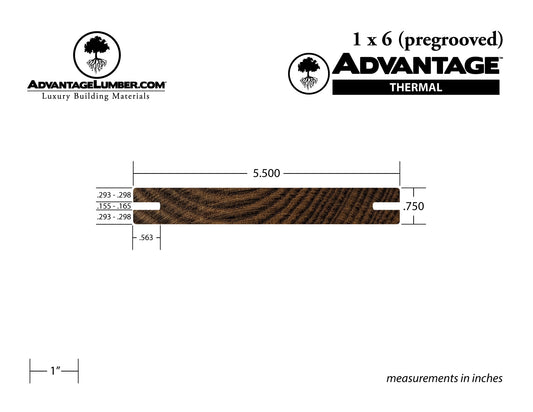

Advantage Thermally Modified Pine, 1x6 Pre-Grooved

Save Liquid error (snippets/price line 86): Computation results in '-Infinity'% Call to Order: 1-877-232-3915Regular price $3.15 USDRegular priceUnit price per -

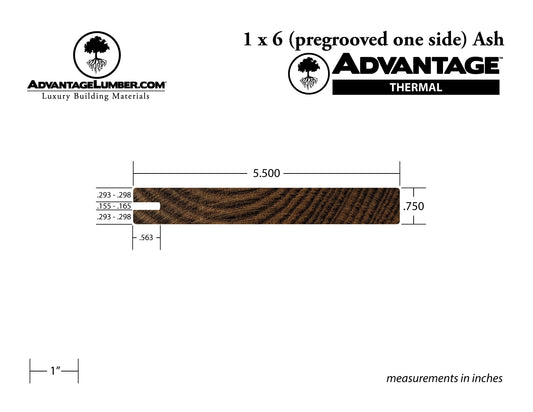

Advantage Thermally Modified Pine, 1x6 One-Sided Pre-Grooved

Save Liquid error (snippets/price line 86): Computation results in '-Infinity'% Call to Order: 1-877-232-3915Regular price $3.15 USDRegular priceUnit price per -

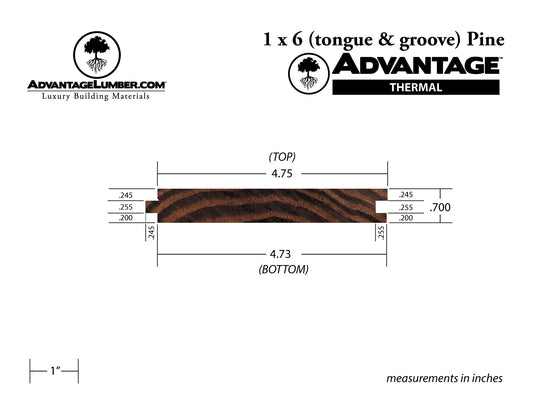

Advantage Thermally Modified Pine, 1x6 T&G Square-Edge

Save Liquid error (snippets/price line 86): Computation results in '-Infinity'% Call to Order: 1-877-232-3915Regular price $3.40 USDRegular priceUnit price per -

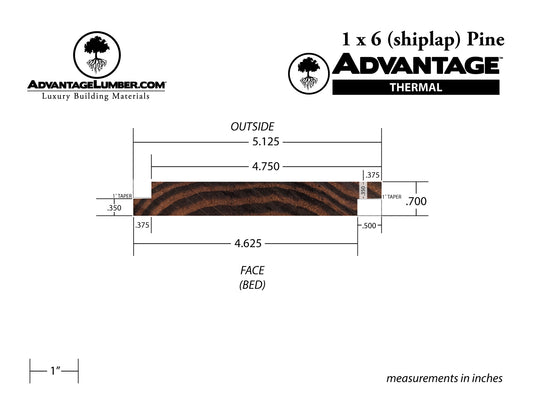

Advantage Thermally Modified Pine, 1x6 Shiplap

Save Liquid error (snippets/price line 86): Computation results in '-Infinity'% Call to Order: 1-877-232-3915Regular price $3.40 USDRegular priceUnit price per -

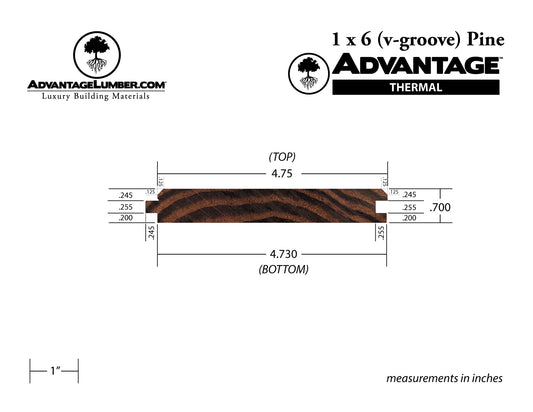

Advantage Thermally Modified Pine, 1x6 45° V-Groove

Save Liquid error (snippets/price line 86): Computation results in '-Infinity'% Call to Order: 1-877-232-3915Regular price $3.40 USDRegular priceUnit price per -

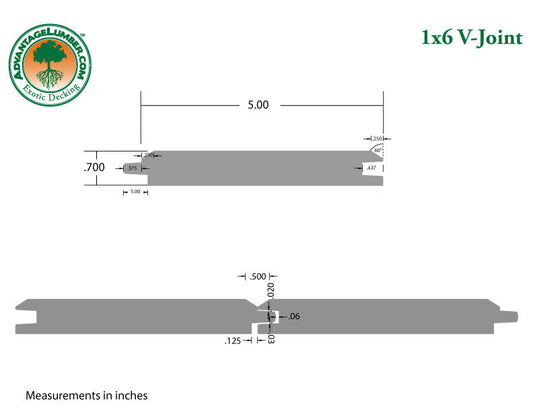

Advantage Thermally Modified Pine, 1x6 60° V-Joint

Save Liquid error (snippets/price line 86): Computation results in '-Infinity'% Call to Order: 1-877-232-3915Regular price $3.40 USDRegular priceUnit price per -

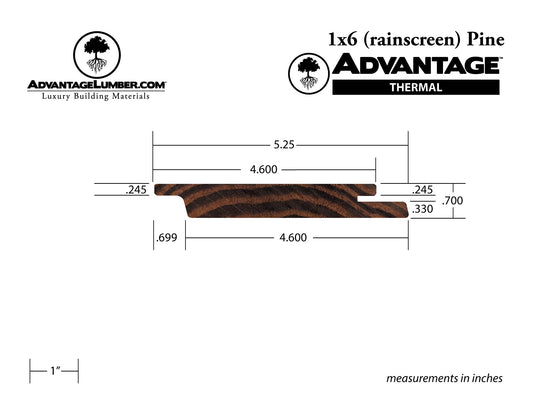

Advantage Thermally Modified Pine, 1x6 Rainscreen

Save Liquid error (snippets/price line 86): Computation results in '-Infinity'% Call to Order: 1-877-232-3915Regular price $3.90 USDRegular priceUnit price per -

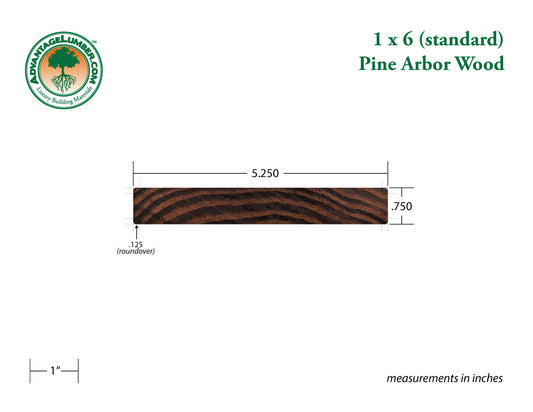

Arbor Wood Thermally Modified Natrl Pine, 1x6 Standard

Save Liquid error (snippets/price line 86): Computation results in '-Infinity'% Call to Order: 1-877-232-3915Regular price $4.15 USDRegular priceUnit price per$0.00 USDSale price $4.15 USD -

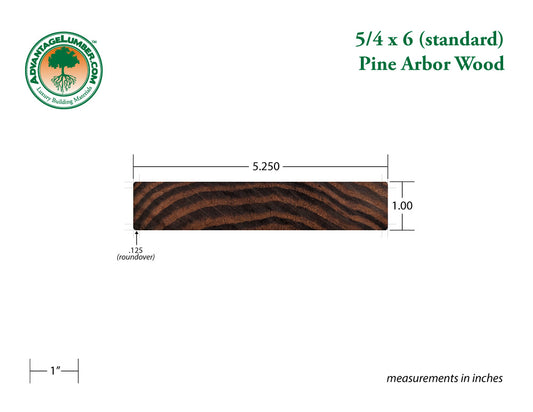

Arbor Wood Thermally Modified Natrl Pine, 5/4x6 Standard

Save Liquid error (snippets/price line 86): Computation results in '-Infinity'% Call to Order: 1-877-232-3915Regular price $4.25 USDRegular priceUnit price per$0.00 USDSale price $4.25 USD -

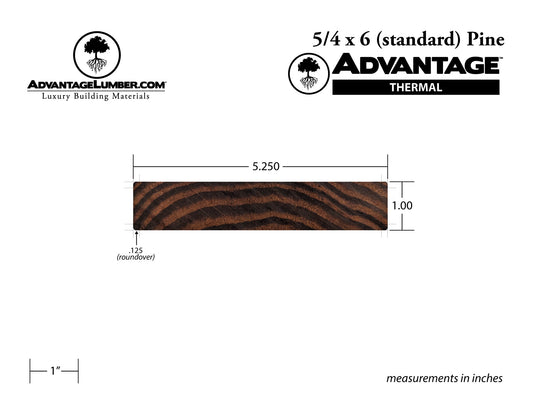

Advantage Thermally Modified Pine, 5/4x6 Standard

Save Liquid error (snippets/price line 86): Computation results in '-Infinity'% Call to Order: 1-877-232-3915Regular price $4.25 USDRegular priceUnit price per -

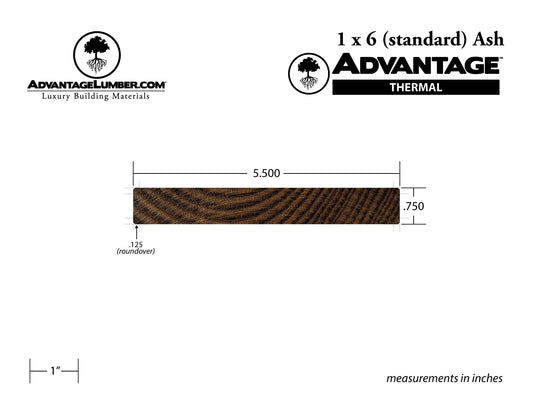

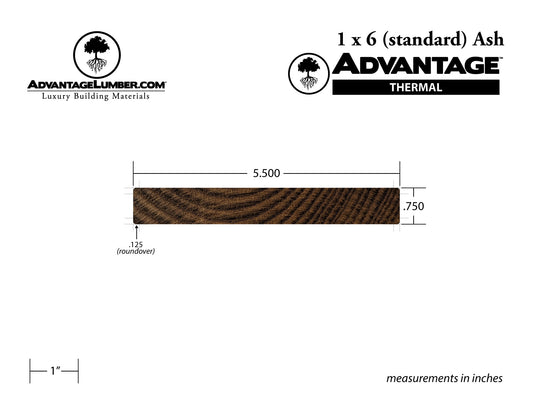

Advantage Thermally Modified Ash, 1x6 Standard

Save Liquid error (snippets/price line 86): Computation results in '-Infinity'% Call to Order: 1-877-232-3915Regular price $4.50 USDRegular priceUnit price per -

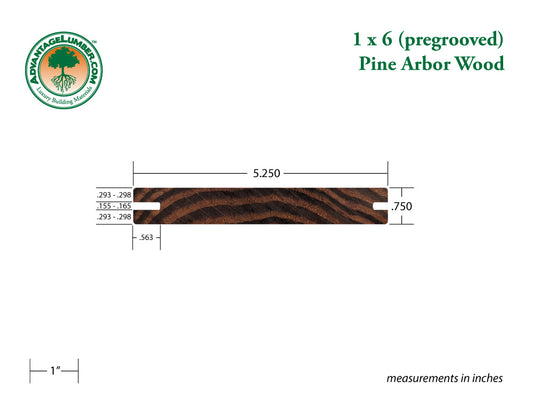

Arbor Wood Thermally Modified Natrl Pine, 1x6 Pre-Grooved

Save Liquid error (snippets/price line 86): Computation results in '-Infinity'% Call to Order: 1-877-232-3915Regular price $4.75 USDRegular priceUnit price per$0.00 USDSale price $4.75 USD -

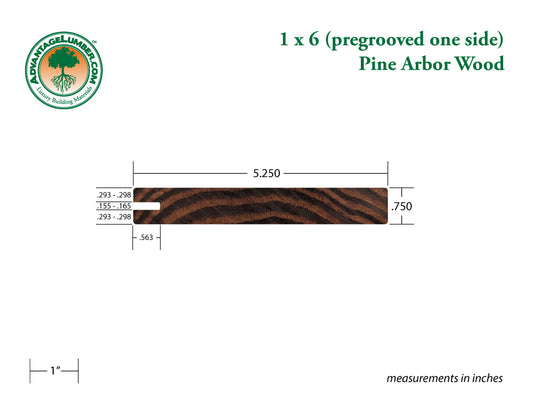

Arbor Wood Thermally Modified Natrl Pine, 1x6 One-Sided Pre-Grooved

Save Liquid error (snippets/price line 86): Computation results in '-Infinity'% Call to Order: 1-877-232-3915Regular price $4.75 USDRegular priceUnit price per$0.00 USDSale price $4.75 USD -

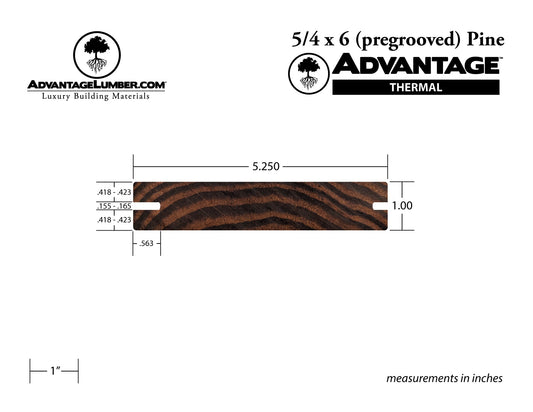

Advantage Thermally Modified Pine, 5/4x6 Pre-Grooved

Save Liquid error (snippets/price line 86): Computation results in '-Infinity'% Call to Order: 1-877-232-3915Regular price $5.00 USDRegular priceUnit price per -

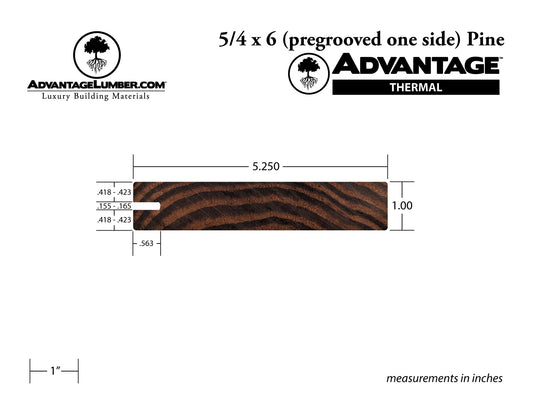

Advantage Thermally Modified Pine, 5/4x6 One-Sided Pre-Grooved

Save Liquid error (snippets/price line 86): Computation results in '-Infinity'% Call to Order: 1-877-232-3915Regular price $5.00 USDRegular priceUnit price per

Complete your Project

-

Accessories

We have all the accessories to get your project done!

-

Wood Maintenance

Wood Maintenance